Industrial high-performance linear actuators became devices that helped increase the power of industrial and scientific advancement leap. There are numerous areas for actuators to implement where they provide automation and remote control reliability.

Areas for the implementation of industrial actuators

Industrial actuators are actively used for the construction of medical furniture, with the backrest of the chair, the height of the couch and the support elements being adjustable. Actuators are also installed on elevators to move disabled and bedridden patients, as well as on stairlifts.

Medical actuators, together with common industrial actuator models, offer low-noise performance, high quality and reliability, represented by dust and moisture protection IP54, IP66 according to the International Protection Standard. Actuators are also used in passenger elevators as the main operating mechanism for lifting people. These actuators always have considerable load latitude and are designed to lift around 200 to 300 kilograms.

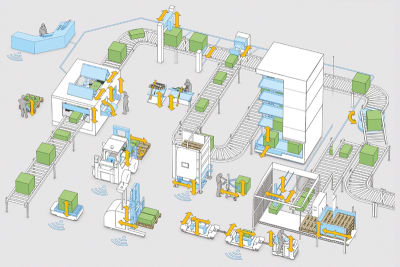

Electromechanical linear drives for general industrial use are compact, high-performance devices that are designed for most production processes with linear displacement. Their technical properties play an important role – indicators of permissible load and speed, smooth running and the ability to work under adverse external influences. Industrial actuators for the automation of production processes make the work of an employee in an industry in which they are used considerably easier.

General industrial automation

Electromechanical linear drives for general industrial purposes are compact, high-performance devices that have been developed for most production processes with linear motion automation. Your technical properties play the most important role. These are allowable load and speed, smooth performance, and the ability to work under complicated environmental conditions for installation. Industrial actuators for the automation of production processes make work considerably easier for employees in every industry in which they are used.

These are areas where general industrial actuators are used:

- Electromechanical linear actuators for machine tools, mechanical engineering, food industry – these are electrical actuators for machining and other types of machines, electrical actuators for belt and overhead conveyors, and industrial actuators to increase the comfort of the worker who controls the mechanism (built-in electric drive, driver’s seat, mirror position control , Bonnet control)

- High-tech production – manufacture of solar panels with electric actuators that allow the solar panels to move directly towards the sun. An electromechanical actuator is also used when installing parabolic satellite antennas. The antenna drive (satellite drive) is an important component for proper control.

- Industrial ventilation systems – Use of sliding panels for hoods to automate the process of regulating air flow. It is very important to choose the right type of actuator for industrial purposes so that all the needs of a particular production are met. If you have difficulty choosing an industrial actuator, you can always get help from the actuator manufacturer’s help center. For example, Progressive actuators always helps their customers choose the most suitable equipment that meets all requirements. Make the right selection of the required electrical actuators as well as select additional functions and additional supporting devices such as control units for electrical actuators and remote controls for optimal control of the actuator as well as various additional accessories such as brackets, electrical relays, etc.

Automation of agricultural actuators

Every day, more and more industries are being improved and automated to make the work of workers easier and to increase efficiency and productivity. This is especially true in difficult and labor-intensive areas in which devices and people sometimes work under extreme conditions.

Agriculture is just one of these industries. Therefore, linear automation with electrical actuators is widely used today. The mechanization of various agricultural machines, livestock, the process of harvesting feed and agriculture – all of these can be effectively improved using linear motion technology.

Using linear motion automation has never been easier. Through the implementation of such intelligent technologies, which make it possible to make everything more important in a timely, correct and automatic manner, various industrial areas have become easier to understand and more convenient to handle. Use linear actuators now and go progressive!

TopsDecor.com Home Decor Ideas

TopsDecor.com Home Decor Ideas