Carpenters play an inevitable role in decorating the interiors of our homes with furniture. In carpentry, the basic technique for fastening pieces of wood is called a dovetail joint. The basic function of such joints is the resistance that they offer when pulled apart. This technique comes from the past and is now one of the most popular work techniques among carpenters.

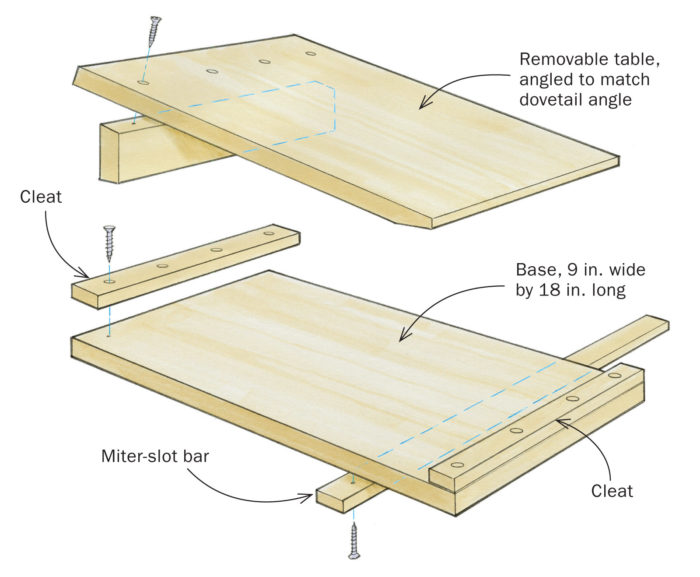

With the advancement of carpentry tools, a device called dovetail devices is also invented that holds the wood vertically to cut dovetail joints with a router. You can shop best dovetail devices from various online shopping sites.

Now let’s understand how dovetail connections are made.

Take all necessary precautions:

For any type of carpentry, it is always helpful to keep all requirements and tools at arm’s length. So collect your tools and keep them systematically on a table you will be working on.

The basic needs are wooden blocks (5 inches x 3 inches x 3 inches), pencil for important markings, a chop saw, a back saw, two or three chisels as much as you want, a mallet and a hammer. If you want to make more fixtures now, you can use more tools and raw materials. And keep the work area clean.

Measure and mark necessary markings on the forest:

Next, you need to measure the pins and tails accurately. It is an integral part of dovetail manufacturing and it is very difficult to set dimensions. You can start with the piece of wood on which you want to make the pens.

If you measure 10 mm from both sides of the wood, you can easily find the middle. Then make three pen marks of the same size. Then do the same with the piece of wood you want to tail on.

Cut the pins and tails according to the markings:

Now the cutting part comes. Take your saw, chisel and hammer and cut the pins and tails according to the markings you made. Take the pinned wood and attach it to the dovetail gauge.

Now cut out the pins and simply follow the reflection in the saw when cutting to ensure that a square interface is created. Now do the same with the tailwood. After completing both steps, you can see how the two fit together. If you find that someone needs more precision, you can use chisels and hammers and make certain changes.

Remove the pen and tail waste:

The distance between the two pins and two tails can be made with the back saw. Apparently, a lot of waste will come out. You can remove the waste with a chop saw.

The pencil waste is removed by turning the wood 90 degrees and cutting the depth line so that the outer parts of the outer edges are removed. The final waste can also be removed using the same method. After removing the waste, you should check the pins and tail connections for any changes if necessary.

Make the final fittings:

In most cases, you will find that the dovetails do not fit perfectly. In some places they are

are tight and loose in some places. Well, you should use a chisel and slowly remove the excess part from pins or tails.

However, be careful not to remove any material from the edges. It is even preferable to remove materials from both pins and tails. Now adjust the joints and your dovetail will be completed.

Always remember that carpentry is all about practice. You cannot become an expert overnight. Likewise, dovetail production cannot be mastered in one day. In the first few days you will make many mistakes and many imperfections, but you will be an expert when you practice.

TopsDecor.com Home Decor Ideas

TopsDecor.com Home Decor Ideas